What is a roller cone bit and what are the classifications of roller cone bits?

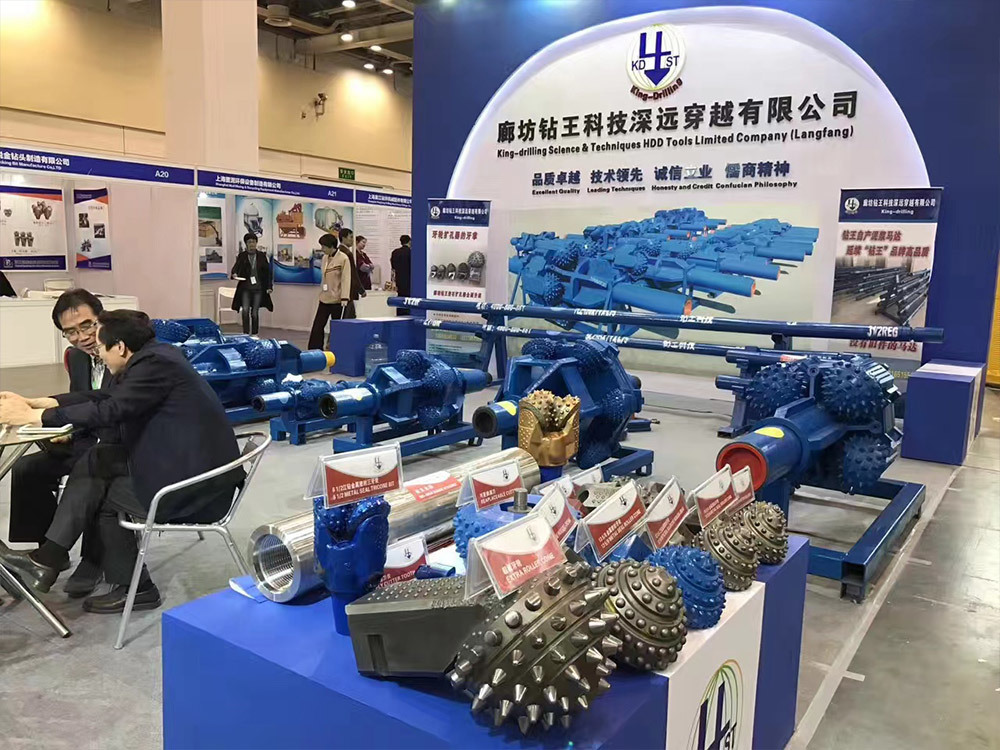

A roller cone bit is a tool for breaking rock in the earth's crust. The cone bit used in oil drilling and other mining drilling can be divided into single cone bit, two cone bit, three cone bit, etc., all of which are composed of tooth palm and tooth wheel with cutting teeth.

Apr 19,2023

Production process of cone bit & working principle of three cone bit

The basic structure of the three-cone bit: the bit body: there are three pieces of teeth assembled and welded together, and the upper part is connected with the thread cone: a tapered metal body composed of the cone body and teeth. Two types of bearing and its oil storage sealing device nozzle

Apr 19,2023

Water well drill pipe explains some common sense problems of drilling

Well drilling is a very deep technology. The primary method of drilling is to find underground water lines. If you find the wrong place and can't get water, it's a waste of energy. Now that technology has been developed, the method of finding the groundwater level is more scientific and accurate. In the past, the experience of drillers was to find underground water lines. However, water well drill pipe summarizes many methods based on experience and has been used until now.

Apr 19,2023

The use of non-excavated reamers requires attention to the following aspects

The metal seal is a high-speed drill bit, and the speed that can withstand is about twice that of the rubber seal. At a higher speed, the metal seal still has a sealing effect on the bearing. This also has to make us think, whether it is possible to increase the service life of the rubber sealing cone by increasing the tension and controlling the speed?

Apr 19,2023

The rotation speed and tension of the cone reamer are very important parameters, but unfortunately, many drilling rig manufacturers do not have the number of turns per minute of the drill pipe on the instrument.

Apr 19,2023

What other tests are needed for finished drill pipes to leave the warehouse?

The production of a drill pipe requires many process steps. After the drill pipe is made into a finished product, further testing is required. The magnetic flux leakage testing method described below: the drill pipe is a thin-walled pipe and bears the effects of axial force, bending moment, centrifugal force, torsional force and dynamic load during the drilling process. The working conditions are extremely harsh.

Apr 19,2023

What are the points for attention of drill pipe?

Pay attention to avoid mixing drill pipes with different buckle types; Do not mix drill pipes even if they are not made by the same manufacturer (because the technical parameters, processing methods, tools and mechanical equipment used by different manufacturers are different, and the tolerance and close distance of the processed drill pipes will be different); Do not mix drill pipes with too much difference between the old and the new and with too much difference in wear degree to avoid construction risks.

Apr 19,2023

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

Hot Information